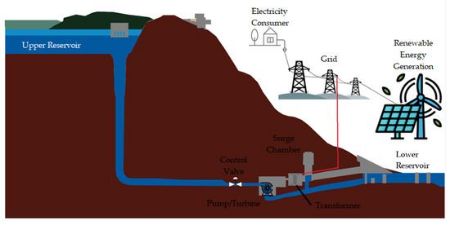

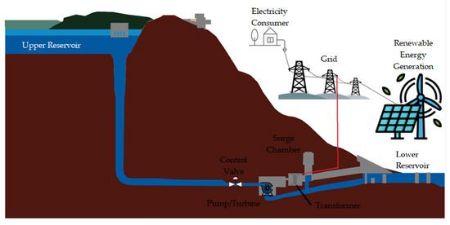

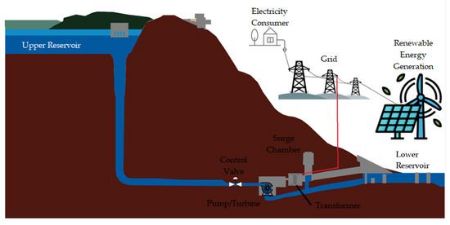

Friday, August 22, 2025 Pumped Storage Hydropower (PSH) is a proven and essential technology for storing excess electricity and balancing energy grids, especially with rising renewable energy adoption. By using two reservoirs at different elevations, PSH stores energy during low demand and generates electricity during peak periods. With projects in the UK, Australia, and worldwide, PSH supports sustainable energy, economic growth, and grid stability while integrating civil and geo-environmental engineering expertise.