The Panama Canal is one of the most remarkable feats of civil engineering in history. Its construction connected the Atlantic and Pacific Oceans, revolutionizing global trade, and demonstrating the sheer power of human ingenuity and engineering prowess. This text explores the importance of civil engineering in creating and operating the Panama Canal, detailing the structural complexities and the engineering solutions that addressed the significant challenges encountered during and after its construction.

Importance of Civil Engineering in the Panama Canal

The Panama Canal's construction showcased extraordinary civil engineering achievements. Initially, the French began the excavation in 1882, inspired by their success with the Suez Canal. However, due to their lack of understanding of the tropical climate and diseases such as malaria and yellow fever, the French efforts failed. The importance of civil engineering became even more apparent when the Americans took over the project in 1904.

Under American management, the project saw significant advancements. The U.S. Army Corps of Engineers played a pivotal role, utilizing extensive planning, a virtually limitless budget, and innovative engineering techniques. The introduction of the steam shovel allowed for massive earthworks, critical for overcoming the challenging geological conditions in the Culebra Cut, where the canal traversed the highest ground between the oceans.

Structural Complexities and Engineering Solutions

Disease Control:

One of the critical factors for the success of the canal was the control of diseases. Understanding the role of mosquitoes in spreading malaria and yellow fever led to effective measures by William Gorgas, who implemented strategies to reduce mosquito breeding grounds. This significantly reduced the mortality rate among workers.

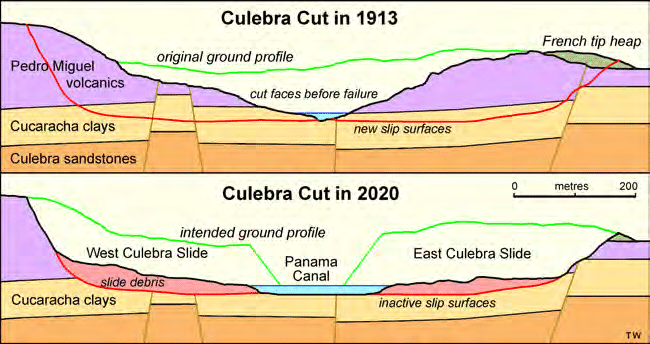

Simplified cross-sections of the Culebra Cut looking towards the northwest, in 1913 and therefore late in the construction phase, and also now after the development of the two large landslides and the removal of most of their slipped debris

Gatun Lake and Locks:

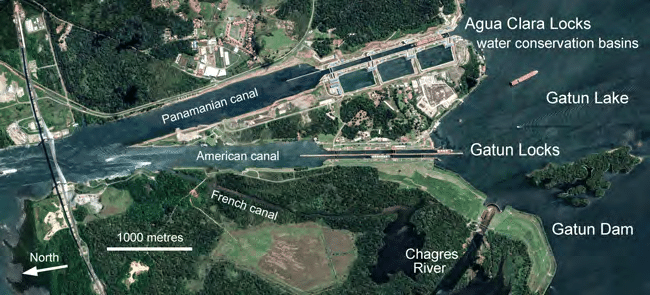

The creation of Gatun Lake was a masterstroke in civil engineering. By damming the Chagres River, the Americans created a large artificial lake that facilitated the canal's operation and controlled flooding. The original plan for multiple locks was simplified to a series of three locks at Gatun, streamlining the process of raising and lowering ships.

Old and new locks out of Gatun Lake at the Atlantic end of the Panama Canal. The Earth components of the Gatun Dam are the entire areas covered in paler green grass, with the curved crest of its concrete spillway at the center above the Chagres River. (Base images from GoogleEarth.)

Culebra Cut Excavation:

Excavating the Culebra Cut was one of the most challenging aspects of the project. The cut required digging through strong volcanic rocks and dealing with landslides caused by weak clays in the Cucaracha Formation. Engineers managed these issues through extensive drilling and blasting, employing steam shovels and floating dredgers to remove the debris.

Landslide Management:

Landslides were a recurring problem during and after the canal's construction. The engineers allowed the canal to fill with water ahead of schedule, enabling floating dredgers to remove slide debris efficiently. Although initially misunderstood, this method eventually helped stabilize the slopes.

Modern Upgrades:

In response to the increasing size of ships, the Panama Canal underwent significant upgrades, including the construction of new, larger locks completed in 2016. These 'Neopanamax' locks allow much larger vessels to pass through, ensuring the canal's continued relevance in global trade. The new locks also feature innovative water-conservation basins that retain and reuse water, addressing the critical issue of water management.

Additional Details on Engineering Solutions

Volcanic Rock Excavation:

The presence of strong volcanic rocks like andesites and basalts in the Culebra Cut required significant drilling and blasting. The Pedro Miguel Formation, which consisted of andesites, tuffs, and agglomerates, was particularly challenging. Engineers used large quantities of dynamite and heavy machinery to break and remove these rocks.

Geological Challenges:

The complex geology of the region, with numerous faults and varying rock formations, posed additional challenges. The engineers had to deal with different levels of stability across the canal's length, particularly where the weaker Cucaracha clays were present. Understanding the geological structure was crucial for planning effective excavation and stabilization methods.

Flood Management:

Construction of the Madden Dam on the upper Chagres River in 1935 improved flood control and ensured a reliable water supply for Gatun Lake during the dry season. This was essential for maintaining the water levels needed to operate the locks efficiently.

Water Conservation Basins:

The new locks built in 2016 incorporated water-conservation basins, which retain and reuse 60% of the water during each lock cycle. This innovation was critical in managing the limited water resources of the Chagres River basin and ensuring the canal's sustainability.

Innovative Lock Designs:

The new locks also featured massive sliding gates instead of traditional hinged gates, enhancing their durability and efficiency. The omission of electric mules for guiding ships reflects modern advancements in ship maneuverability, although it posed new challenges for navigation within the locks.

The Panama Canal is a testament to the transformative power of civil engineering. From disease control to groundbreaking earth-moving techniques and innovative structural solutions, civil engineering was essential in overcoming the immense challenges posed by the project. The canal's continued operation and upgrades reflect the ongoing importance of engineering ingenuity in maintaining and enhancing this vital global trade route. The Panama Canal not only stands as a monument to human achievement but also as a living example of the enduring importance of civil engineering in shaping our world.

If you want to learn more about Panama Channel, read this article.